Dowel bar used in Cement Road Construction is a short, round and smooth steel bar which is used to provide a mechanical connection between two road slabs, without restricting horizontal joint movement due to moving loads of vehicles.

These bars are mainly used in jointed plain concrete pavement (JPCP) to bear the additional stress and loads, imposed due to movement of vehicles.

Function of Dowel Bars

Dowel bars serve various functions such as :

- They transfers load from one concrete slab to adjacent concrete slab in such a way that two consecutive slabs move together and thus reduce impact loading developed by the slabs by their independent movement.

- They help reduce faulting of joints and cracking of corners.

- They also hep in improving performance of pavement joints.

Sizes of Dowel Bars

- The size of dowel bars depends on the thickness of pavement slab.

- Most of the times, dowel bars are 18″ i.e. 460 mm long and 1.25″ (32 mm) to 1.5″ (38 mm) in diameter.

- They are spaced 12 inches i.e. 305 mm apart.

Materials of Construction for Dowel Bars

As dowels bars can get exposed to rain water, it is necessary to protect them from corrosion. Dowel bars are generally made from stainless steel. Or they may be made of carbon steel with epoxy coating.

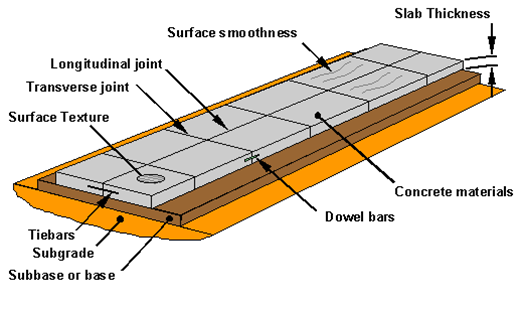

Placement of Dowel Bars

- Dowel bars are placed across transverse joints of concrete pavement slab to allow relative movement during vehicle motion.

- They are inserted at the mid-depth of the concrete slab.

- They are coated with cement-steel bond breaking material so that they can freely move inside slab concrete.

- Their free movement ensures transfer of loads as well as allowing expansion and contraction of adjacent slabs independently.

- It is important to place dowel bars in parallel to the center line of road.

- When it is necessary to place dowels at cracks in slab, new channels must be cut so that at least one-half dowel can be on each side of crack.

Installation of Dowel Bars

Installation of dowel bars require following tools

- DowelBaskets

- Dowel Bar Inserter (DBI)

A bond breaker material like grease must be applied prior to placement of dowel bars.

Problems during installation of dowel bars can be :

- Missing Bars

- Misplaced bars due to poorly adjusted equipment

- Damaged dowel baskets

- Improper basket anchoring

- Concrete around bars is poorly compacted.

- Too stiff concrete mix is used.