Concrete slabs appear to be solid and hard, but in reality, concrete is moist stuff. It begins as a liquid slurry of water and aggregate, and even after it hardens, moisture continues to pass out of the concrete for years. Concrete can also absorb and transfer ground moisture.

While this quality of concrete doesn’t make much difference for outdoor applications, such as patios or walkways, it matters a great deal indoors, especially when you intend to install residential flooring on the concrete slab.

Concrete Moisture Levels Can Affect Flooring

Moisture can be a problem when a floor that looks dry really isn’t. Because concrete is permeable, ground moisture can slowly seep upward in the form of vapor and adversely affect anything that rests on it. If given ample space, warmth, and ventilation, water vapor will simply evaporate. But when flooring is laid directly on the concrete, it effectively creates a water-tight, air-tight barrier. Moisture builds up and has nowhere to go.

Trapped moisture creates havoc that you do not need:

Moisture is conducive to the growth of mold and mildew.

Moisture can cause organic flooring materials (such as solid hardwood, engineered wood, cork, or bamboo) to degrade.

Moisture can cause any flooring to bow, warp, and bubble.

Methods for Testing Moisture Levels

It is vitally important to test your concrete slab’s moisture before installing flooring over it. The definitive test is with a calcium chloride kit or a relative humidity meter. Testing with either method will tell you how precisely how much moisture is present, making it possible to choose a surface flooring that is appropriate. Flooring manufacturers rate their products based on the moisture levels they can tolerate, and testing your slab can tell you if a particular flooring material is likely to perform adequately.

Plastic Sheet Test (ASTM D 4263)

The plastic sheet method was developed by ASTM International and involves taping a plastic sheet to the surface of the concrete to create a vapor-proof seal around the plastic. The sheet is left in place for 72 hours, then a dewpoint hygrometer is used to test the level of moisture that is in the air under the sheet. This tells you how much evaporation occurred over the course of the 72 hours.

To get a general idea of moisture content in your newly constructed slab, following Plastic Sheet Testing can be done easily.

Tools and Materials that you will need are as follows :

- Clear plastic sheeting

- Duct tape

Instructions

- Cut clear plastic sheeting into several 24 by 24-inch squares.

- Inspect the Concrete to make sure that the concrete where you intend to place the plastic is free of standing water, as this will distort your test results.

- Tape the plastic squares securely to the concrete with duct tape or any other kind of waterproof tape.

- Firmly press down all sides of the tape to prevent moisture from escaping.

- Wait at least 48 hours, then check the plastic to see if any moisture has beaded up on the inside of any of the plastic squares.

- Moisture on the inside of the plastic, either in the form of water droplets or fogginess, indicates the slab is expelling moisture in measurable amounts.

- Before choosing any surface flooring to install on such a slab, a more precise test using a calcium chloride test, or a measurement with a relative humidity meter, is necessary.

Relative Humidity Test Using Probes (ASTM F 2170)

This method involves drilling a hole into a concrete floor and inserting an electronic meter into it, or embedding the meter in the concrete before it has cured. The relative humidity of the concrete is then tested over the course of 72 hours. With this information, the software in the meter is able to determine how much moisture is present through the core of the slab.

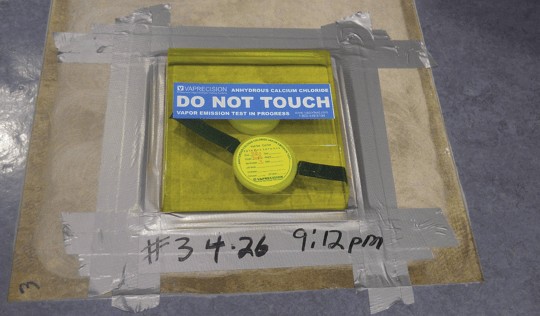

Anhydrous Calcium Chloride Test (ASTM F 1896)

Developed by the Subcommittee on Practices of the Committee on Resilient Floor Coverings, the calcium chloride test is similar to the plastic sheet test in that it uses a sealed environment to determine the amount of evaporation that occurs from the concrete floor over a period of time. The test is conducted in three locations for every 1000 square feet of concrete slab. This allows you to determine the moisture level across the entire surface of the floor, rather than just one specific area.

For each test site, a packet of very dry calcium hydroxide is poured into a container, which is then weighed. The container is then placed on the concrete surface and it sealed over with a plastic enclosure. After 72 hours the calcium hydroxide containers are removed and weighed again. The excess weight indicates how much moisture the crystals absorbed from evaporation out of the concrete.

This information allows you to calculate how many pounds of water vapor are released from every 1000 square feet of space across the surface of the concrete over a 24-hour period. Generally, you do not want vapor emissions to exceed 3 pounds per 1000 feet, although some floor surface coverings will be suitable for environments emitting as much as 5 pounds per 1000 feet.

Concrete Moisture and Flooring Materials

Concrete moisture is more problematic in below-grade (basement) locations where conditions are naturally humid, but it can also be a problem for on-grade slabs as well, especially when they are new. One method for mitigating the problem is to raise the surface flooring slightly off the slab by first laying rows of “sleepers” topped with a plywood sub-floor, so that the surface flooring material does not rest directly on the concrete. This is a very common technique where carpeting is desired.

Generally speaking, the best surface flooring materials for a concrete slab that is still transmitting some amount of water vapor include:

- Ceramic or porcelain tile

- Resilient floorings such as luxury vinyl flooring (LVF)

- Rubber tile

Flooring materials that do not perform well on concrete that is emitting water vapor include:

- Laminates

- Solid hardwood

- Engineered wood

- Carpet

Moisture Resistant Flooring Materials

Some laminates, engineered woods, bamboo, and cork flooring materials identified as moisture-resistant can be used successfully on concrete slabs. Manufacturer’s instructions will indicate if concrete slab installation, below grade or above grade, is regarded as appropriate.

Where an above-ground concrete slab is sufficiently cured and is no longer transmitting water vapor, just about any flooring material can be used.