RCC Columns are the main load bearing members in RCC Framed structures. Strong and leak proof formwork must be constructed to pour concrete so that water cannot leak and honey combing of RCC would not occur. Weak formwork may cause column blowout during RCC column construction.

RCC Columns can be mainly of four shapes :

- Square Columns

- Rectangular Columns

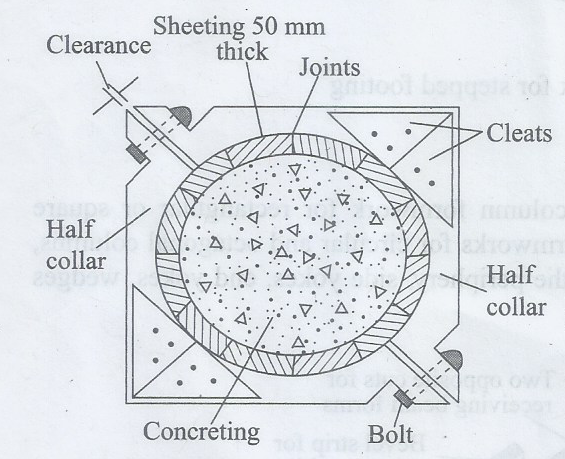

- Circular Columns

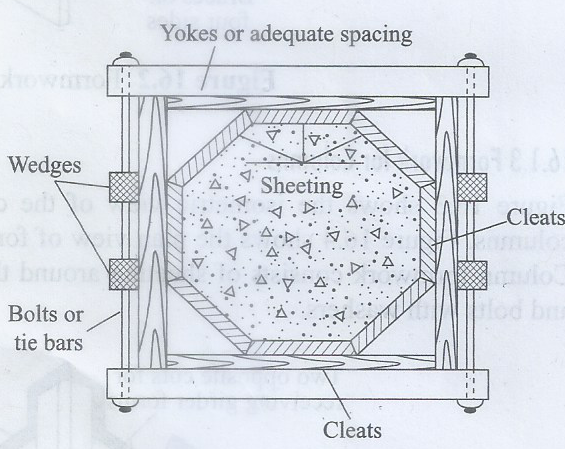

- Octagonal Columns

Columns carry the load of the structure and hence they are critical. It is important to align them for verticality so that load is transmitted properly to foundation. Column shuttering shall be strong enough to take the pressure of column concrete and remain in position during concreting.

Procedure of Column Shuttering

Fabrication of Starter Pad

To hold the concrete shuttering firmly in place with proper alignment, a concrete pad called “starter” is cast before fixing the suttering.

Thickness of this starter pad is about 45mm to 60mm and length/breadth of this starter is precisely the same as dimensions of column. Starter pad should be cured for day or two so that it is hard enough to fix the shuttering around it.

Shuttering

Column box or shuttering for column is made of plywood sheets or steel sheets, fabricated with additional stiffeners.

A thin film of oil or grease should be applied to the inner surface of the shuttering to enable easy removal of the column shuttering after the concrete hardens.

Shuttering shall be properly aligned to its verticality and diagonals should be checked to ensure accuracy in dimensions.

Shuttering shall be thoroughly supported with props or ties before pouring the concrete so that it does not move horizontally or vertically during concreting.

Gaps near the shutter joints should be sealed to prevent any leackage of slurry.

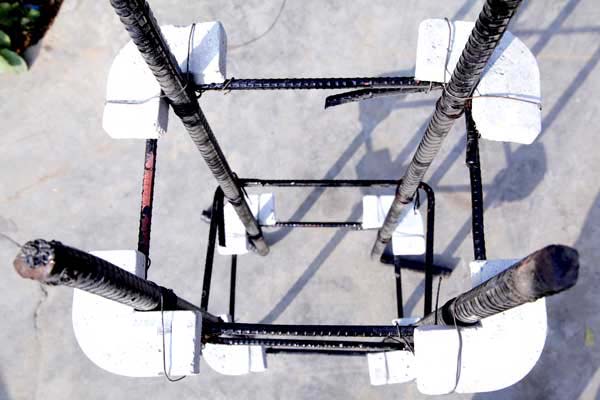

Appropriate space should be provided between the inner face of shuttering and reinforcement by fixing cover blocks.

It is preferably to remove covers after 24 hours of casting. If they need to be removed earlier, they should not be removed before 16 hours.

Removal of shutters has to be done gently and without any jerks and hammering so that edges of columns are not damaged.

Care to be taken during column shuttering

- Starter should be built to hold the shuttering and prevent it from movement

- Diagonals of the shuttering should be checked to ensure dimensional accuracy.

- Gaps at shutter joints should be sealed and cover blocks placed.

Components of RCC Column Formwork

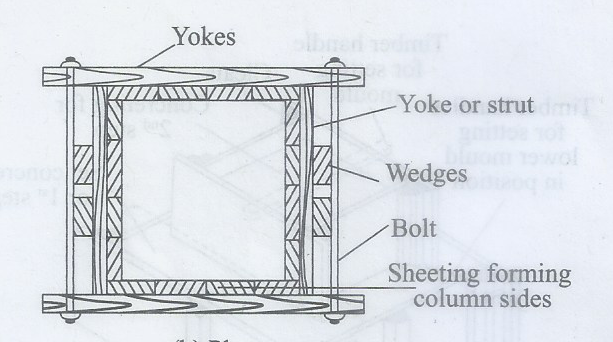

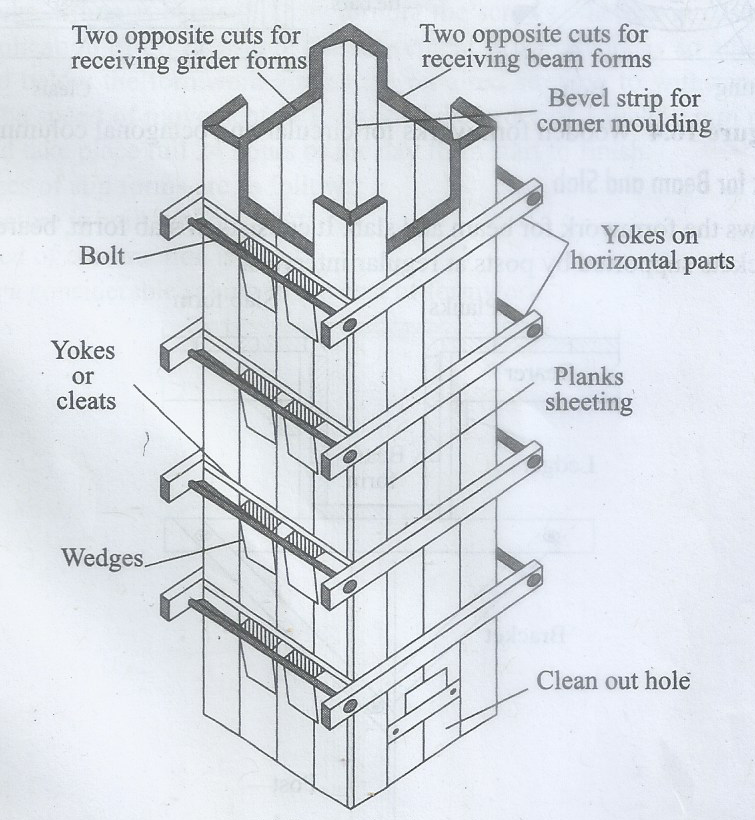

Column formwork consists of sheeting around the periphery, side yokes, end yokes, wedges and bolts with washers.

Period of removal of RCC Column Formwork

RCC Column formwork can be removed after 1 or 2 days. Keep formwork preferably for 2 days.