Various clay tiles are manufactured in different regions of India. They serve as good covering materials for sloped roofs. Tiles are supported over battens, which are in turn supported by rafters. Special Shaped tiles are manufactured to be used for ridges, hips and valleys.

Roofing tiles are a good alternative to plain galvanized iron sheets, corrugated sheets and timber. The roofing tiles used should be leak-proof, easy to handle and hard enough. The fixing of these tiles should be easy and durable.

Various types of roofing tiles are available in market. Out of these, Allahabad tiles and Mangalore tiles are excellent interlocking tiles. They are attractive in appearance also.

- Pot Tiles

- Flat Tiles

- Corrugated Tiles

- Allahabad Tiles

- Mangalore Tiles

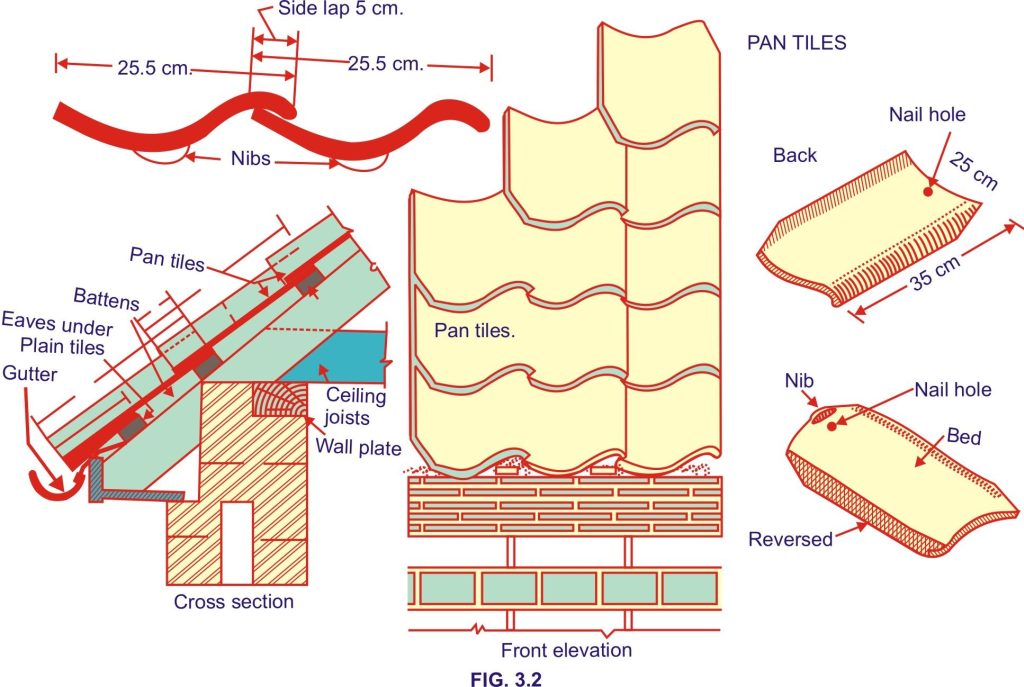

Pan Tiles

Pan tiles are curved in sections. These are 33 cm to 38 cm long and 23 cm to 28 cm wide.

- Implements needed for its moulding are a mould, a horse, a bow and a strike.

- For moulding pan tiles, a ball of prepared clay is pressed well to fill all corners of the mould.

- All surplus earth is cut with the bow and removed.

- Strike is then passed over the wet top of tile in mould. It is done so many times as to render the top surface of tiles smooth.

- The tile is then carefully removed and placed over an already burnt tile to dry.

- After the tile has dried a little it is then placed on the curved top of horse and pressed with hand to make it curved.

- After another five to six hours the raw tile is once again shaped on the horse and its edges trimmed with a sharp knife.

- To stop the clay from sticking to the mould or horse their top is sprinkled over with ash every time before use.

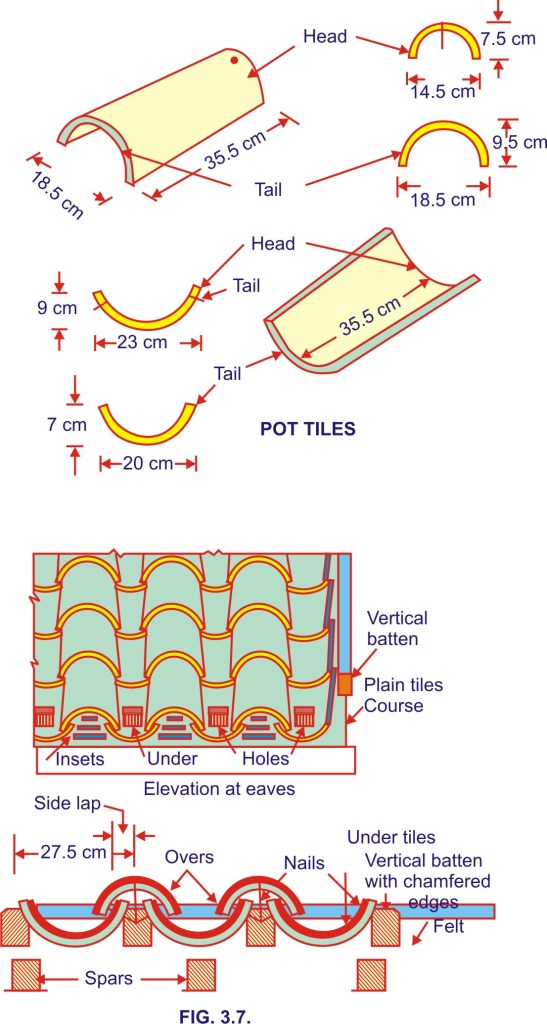

Pot Tiles

Pot tiles are semi-circular hollow tiles having tapering dimension in the longitudinal direction. The length of these tiles varies between 15 cm to 25 cm. These tiles are manufactured by a potter on potter’s wheel. Polishing is done on inner and outer sides with the help of the wet cloth.

They are placed in a position such that their concave and convex faces upward alternatively so that they can become self-locked. These tiles are also known as locking tiles. These are ordinary tiles, having high absorption value. Due to this reason, these tiles are liable to break easily and suffer greater tear and wear. The drainage of water in this type of roof tiles is speedy. They are not so much durable.

Flat Tiles

Flat tiles are rectangular shaped tiles free from distortion and cracks. The tiles should be uniform in size and shape. Two or more holes are drilled in these types of tiles. These holes help in fixing the tiles on the battens. Proper overlap is provided at sides and edges during the fixing of tiles. The compressive strength should be above 75 kg / cm2 and water absorption value should be below 20% for flat tiles.

Corrugated Tiles

Manufacture and placement of corrugated tiles resembles flat tiles. Only difference is that these tiles have corrugations.

- Aside lap of one or two corrugations is formed during the placing of these tiles over the roof.

- There is an edge lap while placement of these tiles.

- After placing they give the appearance of corrugated galvanized iron sheets.

- View of these tiles is nice and the drainage of water over these tiles is very good.

- Avoid using these tiles in the areas where violent winds are frequent.

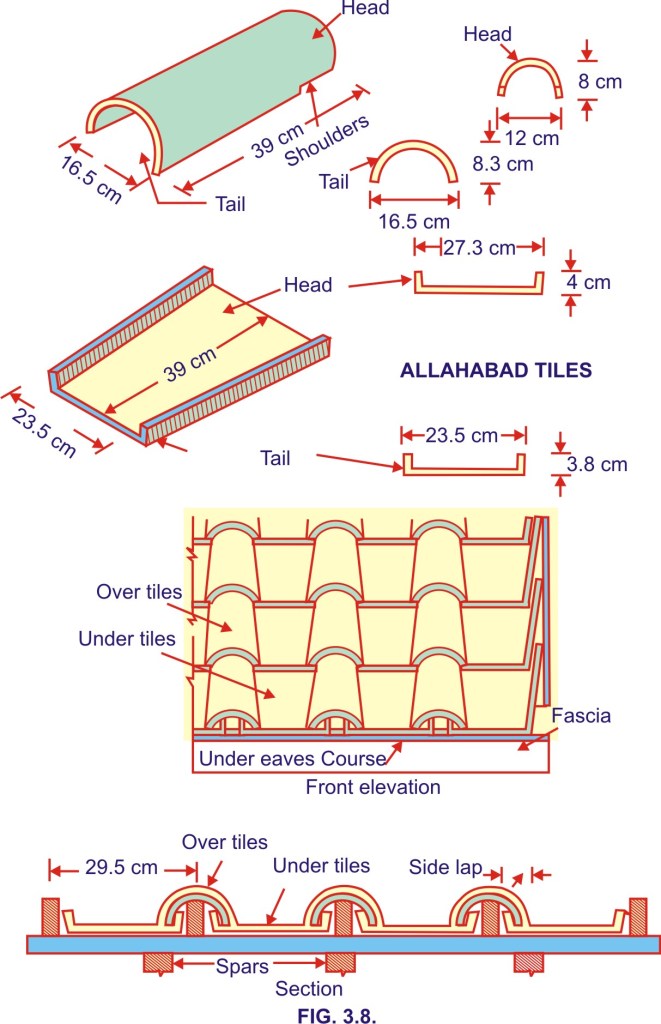

Allahabad Tiles

Allahabad tiles are made using a higher quality of clay. The moulding of the clay is done using machines under pressure. These tiles are composed of two parts :

- Under Tiles : Channel Shape

- Over Tiles : Semi circular Shape

Both of these parts have tapering dimensions with the same length.

During process of covering the roof, the channel tiles (also known as under tiles) are laid side by side and the joints between the adjacent channel tiles are covered with semi-circular tiles (also known as over tiles). Wooden battens are used on the sloping roofs over which these tiles are fixed.

Mangalore Tiles

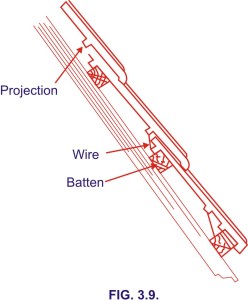

These tiles are named as Mangalore tiles because their early manufacturing was in Mangalore. South-India. These tiles are moulded with machines and have special projections.

These are flat pattern tiles with suitable key projection. About 16 tiles are required to cover one square metre of roof. These projections are much helpful in the interlocking of tiles.

Manglore tiles are very much popular in rural and semi-urban areas of Southern India and Western India. The construction of roofs with the help of these tiles is easy and economical. The average life of Mangalore tiles in estimated as about 25 years with 5 % replacement. The colour of these tiles is mainly red.